OEM Tesla Certified Equipment

Meets Tesla OEM specifications and approval standards.

Rhone 4.2T

-

Drive-on bench with scissor lift

Rhone drive-on bench has been upgraded with a lifting capacity of 4200 kg and 1.32 m height. The most versatile bench facilitates quick diagnosis and straightening with MZ/MZ+ and Cameleon universal bracket sets, pre and post repair reports can be obtained with Celette measuring systems. Thanks to the Celette vehicle loading trolley which enable you to load the damaged vehicles.

Rhone L 4.2T

-

5 m (16.4 ft) long drive-on bench with scissor lift facilitates quick loading

Rhone L is the longer version of Rhone drive-on bench with 5 m long and enhanced lifting capacity of 4200 kg (9260 lb)

Maximum lifting height is 1.36 m (4.25 ft)

Recommended for long wheel base vehicle

Detachable rams provide better access to the vehicle while pulling and measuring

Rhone XL

-

5.8 m (19 ft) extra-long drive-on bench with double scissor lift

4200 kg (9260 lb) lifting capacity to repair all types of light commercial vehicles and long wheel base passenger cars

Lifting height of 1.3 m (51 in.) enables you to work at a very comfortable height for better productivity

Sevenne

-

Complete mobile bench on wheels

Sevenne is a universal mobile bench, which can be upgraded to Rhone or Griffon. The anchoring can be achieved all around the bench, thanks to its peripheral frame for quick fiing of wheels, clamps; multi-function supports; and a steering handle.

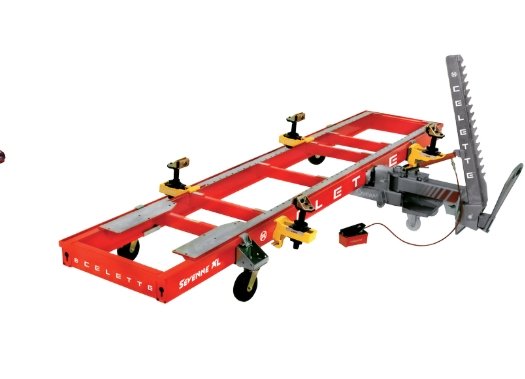

Sevenne XL

-

Extra-long mobile bench on wheels

Specially designed for repairing larger commercial vehicles

Allows positioning under a 2-post lift, and for loading and easily moving between work bays

5.8 m (19 ft) length is suitable for light trucks and commercial vehicles

The universal peripheral frame enables quick anchoring; adjustment of the clamps, wheels, transport handle; and multi-function supports

Griffon XL

-

Extra-long bench with twin lifting system

5.8 m (19 ft) long bench specially designed for repairing commercial vehicles and SUVs

This length enables you to complete simultaneous repairs at both the front and rear of the vehicle

Supplied with 2 independent inner lifting units and a hydraulic tilting system

Autopulse 220-M3

-

A MIG / MAG pulsed generator with 3 integrated wire feeders ideal for car body repairers

Equipped with a digital PFC (Power Factor Correction); supplies pulsed welding quality comparable to three-phase products

Designed for highest performance; features several synergic curves which enables exceptional arc quality

Incredibly versatile; 3 welding torches, for use with multiple materials, including steel, aluminum and brazing (CuSi3/CuAl8), increase productivity for the modern-day workshop

Intuitive interface and high precision wire feed are ideal for car body applications with exceptional welding quality, even when used with thin sheet materials

P3 GYS AUTO

-

The P3 GYS AUTO is a 220 A single-phase synergic MIG/MAG welding unit with 3 integrated wire feeders specially designed for bodywork specialists. It can weld all types of aluminum components with zero spatter. Featuring a highly intuitive color interface, it is capable of welding any type of steel, aluminum or brazing alloy (CuSi3/CuAl8), even thin gauge 0.03" & 0.04", using a pulse function.

Gyspot PTI-G

-

The GYSPOT INVERTER PTI-G spot-welder is the machine of the future. Therefore, the onboard intelligence guarantees full automation, offering body shops the ability to increase their efficiency. The Genius G-clamp with pneumatic over-opening, easy-arm positioning without adjustment, motorized overhanging arm that provides a wide working area. This makes the GYSPOT INVERTER PTI-G the most advanced machine for the active collision repair shop.

Motorized, Adjustable & Ergonomic Overhanging Arm

Extends up to 120cm from the power source

Motorized overhanging arm to adapt to the working height.

Adjustable in height from 159 to 253 cm

Rubber protections at the end of moving parts

Creates easy access to the work area

Smart Welding

AUTO Mode: the machine automatically recognizes – steel type, sheet-metal thickness, Panel bond presence, and insulating material between HSS/VHSS/UHSS/Boron sheet-metal.

Traceability: The recording feature saves the characteristics of each welding spot performed to the SD card provided

Easy transfer of saved reports to PC.

Robust and Mobile

Reinforced and maneuverable trolley with 30-litre coolant tank.

Expander on the front wheels for better stability.

Integrated 6-arm support

Specifications

Welding current: 14,500 A.

Clamping force: 550 daN with 8 bar air pressure.

Liquid cooling of the entire transformer, rectifier, electrodes, and caps.

The new design of the G-clamp cylinder and welding algorithm maximizes productivity

User-friendly navigation using the 5.7″ LCD screen.

Automatic adjustment of the pressure between electrodes.

Spot count feature to determine when you need to change the caps.

Gyspot PTI-S7

-

The Gyspot-PTI-s7-220v-Evolution is the ideal answer to the welding requirements of high strength steels (UHSS/boron), with a clamping force of 550daN, with 8bars air pressure, and a welding current that can reach 14 500Amps

Its C-clamp integrates a high-tech transformer

Brings a solution to limited power supply issues, as it can operate with 16 Amps to 25 Amps fuses only

Operation is extremely easy thanks to the automatic welding parameters setting in easy mode

PREMIUMspot VISION

-

A multi-function spot welding machine in the premium class with complete software package for worry-free automotive repair

Fully automatic welding, particularly for components made of higher maximum strength

Coated and laminated steel panels

Aluminum welding for thin aluminum sheets up to 3 mm

TESLA ALUMINUM MIG WELDING WIRE 4145, 1.2mm